English

Cell Data & Cell Packing

The following seven procedures explain each step that takes place to create the final product.

Previous procedures of LiPo cells production equipment are mainly including vacuum blender, coater, calender machine, etc. Middle procedures are mainly contained die-cutting machine, winder machine, stacking machine, electrode filling machine, etc; Last procedures are including formation machine, grading detection machine, process warehousing logistics automation. Besides, cells production also need packing automation equipment, packing is key procedures of power battery system production and design application.

Laser Welding to Nickel

Traditional thermit welding needs many working stations, waste on resources, difficulty in operation. In addition, traditional soft case batteries cathode tabs welding to nickel, need to cut coil stock nickel strips into fixed length pieces, then worker one hand takes the cell, another hand takes nickel plate, put them to laser machine to fix and weld by eyeballing, any redundant nickel strips in the welded tab will be cut by workers. Above operations are completed by manpower only, it's low efficiency, bad consistency, quality is not guaranteed. In new welding nickel procedure, JinBa adopts new laser welding technique to nickel, laser welding has quality guarantee, hardly exist any welding headwear and tear, intelligently adjust the machine in one key, switch size rapidly and automatically. Testing data shows those laser welding cells are more concentrated on internal resistance, discharge rate, and other important indicator data, also higher consistency.

Intelligent Grading(Intelligent Grading of battery cells)

JinBa intelligent grading technology, applying artificial intelligence method to intelligent grading all kinds of data sets. Plenty of samples make up input data sets, intelligently adjust the machine in one key,switch size rapidly and automatically. The testing machine can time, reset, calibrate intelligently, to indicate belonging to which grading. At the same time, samples will be automatically imported into the system, and every kind of attribute will be accurately divided, to complete grading cells automatically, greatly reducing the risk of misjudging the cells. By analyzing products of known categories, the intelligent data grading system can automatically establish samples such as the K value of the product, so that the internal resistance is more consistent.

Automatic bag sealing technology for electric cells

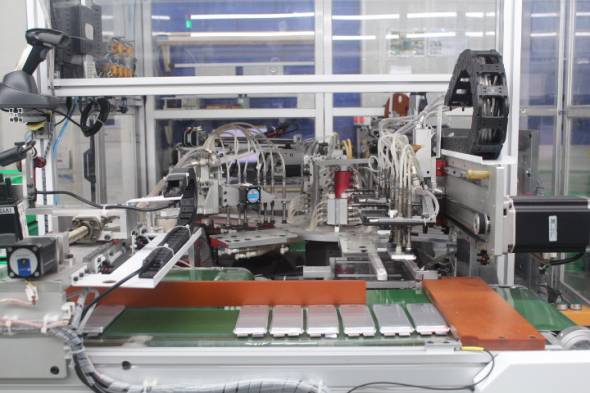

Automatic Taping After Top Sealing

JinBa uses the automatic taping technology after top sealing, to fill the gap of the configuration. It can intelligently adjust the machine, quickly and automatically switch the number, and improve the consistency of the tap position. At the same time, it has the functions of anti-leakage, waterproof, sound insulation and heat insulation. Compared with the traditional operation mode, it's 3 times higher than before. At the same time, the entire test data is automatically uploaded to the system, greatly improves work efficiency and accuracy.

Weighing and Scanning After Side Sealing

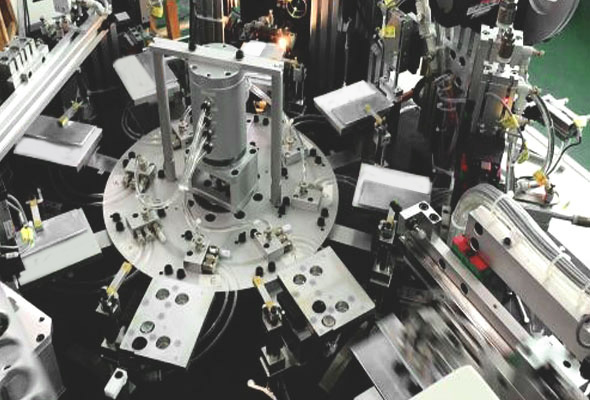

JinBa uses weighing and scanning technology after side sealing, there is a rotary drive mechanism on the frame, we control rotation angle positioning accurately via rotary drive mechanism, to clamp the soft case LiPO batteries by clamp machine, at the same time, the top and bottom sealing structure at two sides of turntable, can seal after the top and side of the battery, intelligent scanning, automatic weighing, automatic zero electricity, including internal corrosion test, and the result will be automatically uploaded to the system. This technology structure is simple and compact, accurate in positioning, and improves overall production efficiency.

Weighing and Scanning After Side Sealing Technology

Traceability System

JinBa traceability system records the product through digital identity management, feedback information from production, personnel, equipment, materials, production time and other processes, providing production procedures and sales, etc. information to improve product quality. It can prevent man-made production accidents in the production process and can achieve accurate directed recall once the problem occurs. At the same time, by scanning the product identification code, the consumer can also obtain relevant information about the product, thereby improving the security of the product and the trust of our brand.

Automatic Acquisition of Environmental Data

JinBa automatic acquisition of environmental data function is mainly used to collect temperature and humidity data of workshop environment operation, to achieve environmental monitoring and control, and upload, save, analyze, deal with collected data, and set standard value to start alarm reminder function, accurate data will be timely transmitted and distributed to relevant process departments to deal with, real-time guidance, response, and reporting of the production dynamics of the workshop, greatly improving the ability to solve problems, and promoting the process of intelligent manufacturing of the enterprise workshop.

Baking Centralized Control System

JinBa design a baking centralized control system that can be operated in a single operation or in multiple joint group operations. The system can upload oven temperature and vacuum to the display panels in real time. Those data which is not meet the indicator, will be alarmed display, the entire procedure will be recorded in system in real time, PDA scans out of box control system, and gives the experimental test results. The system centrally monitors various functions, and provides effective protection for the injection procedure, it has good real-time and stability.